For most operations, Z-Height is critical and can be controlled via the post-processor or edited manually after the post is created. Tech Tip: It is recommended to keep the depth of stock equal to the thickness of the part. Right-Click Stock Manager and select “Edit Definition”. Open the part file to be used for machining and activate your CAM Add-in via Tools > Add-ins > SOLIDWORKS CAM. Step 2: Stock, Setup and Feature Definition I will be adding this tool to Tool Crib 2.įind your newly added tool and hit the Select button in the top left. Select Mill > Tool Cribs and either create a new Tool Crib or use an existing. Next, we need to add our new Tool to the appropriate Tool Crib. Don’t forget to add your preferred Feed Rate settings as we will be passing these values to the post processor.Ĭlick “Save” to add the information into the TechDB. Under Mill Tooling > Flat End Mill choose any existing tool and select Copy.įill out the information on your new custom tool where Tool ID is the name of the tool and D1 will be used as the cutting diameter. The information stored in these are independent from one another and the default is driven by the units set in your SOLIDWORKS document. Tech Tip: In the top-right of the TechDB is a Metric and Inches toggle. The first thing we’re going to do is create a tool in the TechDB that can be used to replicate your cutter. To edit the TechDB, you can either launch it from SOLIDWORKS under Tools > SOLDIWORKS CAM > Technology Database, use the Technology Database icon on your command manager, or you can launch it independently from SOLIDWORKS by navigating to C:Program FilesSOLIDWORKS CorpSOLIDWORKS CAM (x)TechDBApp. The TechDB is used by SOLIDWORKS CAM to store everything from your custom machine and tool information to your materials and feeds/speeds.

Step 1: Customizing the Technology Database If you need help or get stuck in any one area, don’t hesitate to contact your local VAR. Tech Tip: Consider this a quick setup guide and not a replacement for training and/or support. Some things to consider when using SOLIDWORKS CAM for Waterjet/Plasma/Laser Cutting: This includes the ability to customize your SOLIDWORKS CAM to work with your Waterjet, Plasma and Laser Cutters.

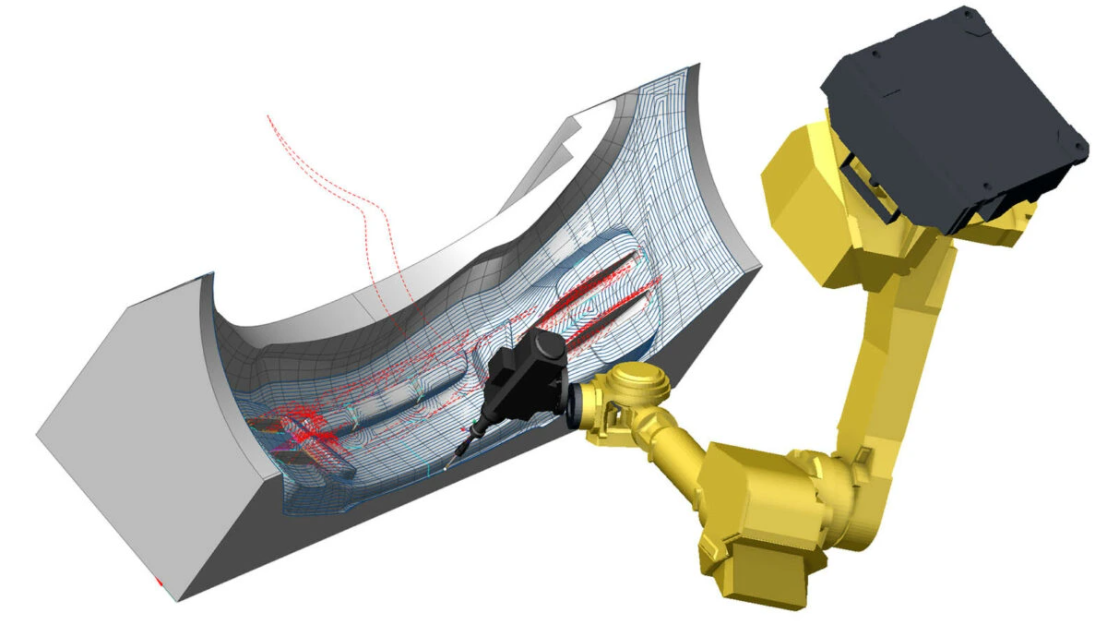

With SOLIDWORKS CAM, all active subscription users get access to 2.5 axis part machining directly inside of SOLIDWORKS.

0 kommentar(er)

0 kommentar(er)